Growing the food of the future

The latest techniques mean plants can be raised in perfect conditions, eliminating the need for harmful fertilizers or pesticides

A laboratory worker in full biohazard gear was patrolling rows of rainbow-colored LED-lit shelves. The shelves stood about 2 meters high and had six levels, each containing trays of lettuce saplings bathing underneath the light, and the room was illuminated in psychedelic pink.

This is not a scene from a science fiction movie, but a common sight for scientists at a plant factory in Anxi, Fujian province, which covers 1 hectare and is the largest vertical farming complex in the world. The second-largest is a 0.64 hectare farm in Newark, New Jersey, in the United States.

| A laboratory worker in biohazard gear checks the growth of lettuce in the vertical farm in Anxi, Fujian province. Zhan Zhuo / For China Daily |

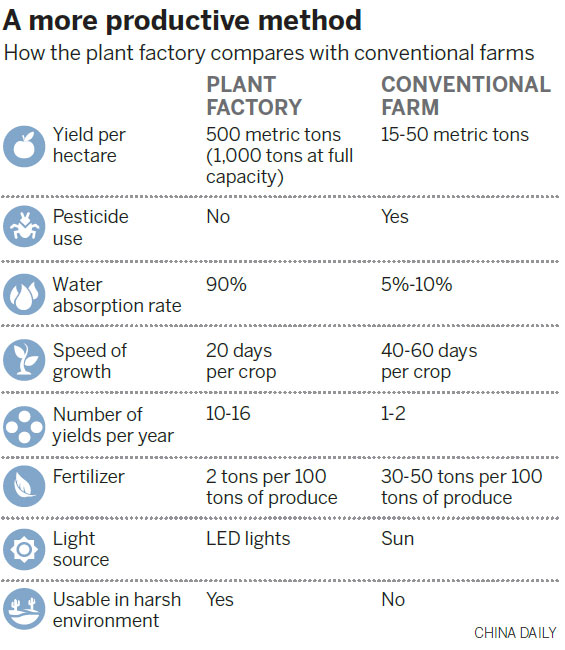

Vertical farming is the practice of growing vegetables and fruits in vertically stacked layers of hydroponic solutions in a controlled, indoor environment. It does not require soil, sun or pesticides and uses far less water and fertilizer than conventional farms.

However, the farm's high-energy costs have greatly limited its scale and profitability. In recent years, scientists have mitigated the issue by inventing energy-efficient LEDs and recyclable hydroponic solutions, as well as new energy-conserving methods to maximize a plant's growth potential.

San'an Sino-Science, the company behind the project, says these new methods have cut the factory's overall energy consumption by 25 percent, compared with its first facility.

"We hope to cut more energy so vertical farming will become a viable way to feed our population," Executive Manager Zhan Zhuo says.

"The technology would also allow astronauts, aircraft carrier personnel and frontier guards on islands or in deserts to grow fresh produce in impossible conditions to fill their daily vitamin and fiber needs."

China has 160 million hectares of farmland dedicated to growing vegetables. Farmers use more than 311,000 metric tons of pesticide and 59 million tons of fertilizer a year, says Li Shaohua, director of San'an Sino-Science's Photobiology Industry Institute.

"The excessive yet inefficient use of fertilizers and pesticides has done great harm to our environment," he says. "It's high time we found a sustainable and green way to protect our food security."

San'an Sino-Science was founded in 2015 by San'an Group and the Chinese Academy of Sciences' Institute of Botany. The second-generation plant in Anxi can produce 1.5 tons of vegetables, such as lettuce and cabbage, a day. At full capacity, it could produce 1,000 tons of leafy greens a year in theory, according to Li.

The perfect environment

Before entering the plant factory, visitors must put on a dual-layered jumpsuit, goggles, a face mask, rubber gloves and boots, and be disinfected from head to toe. Sneezing in the factory is strictly prohibited.

"The standards here are stricter than hospital operating theaters," says Zheng Yanhai, a botany researcher at the institute who works at the plant factory. "Because all the plants are growing in nutrient-filled hydroponic solutions, we do not want germs to get into the liquid and make the plants sick."

Thanks to the clean environment, plants can grow without pesticides. "You can even eat them fresh out of the bag," Zheng says.

In addition to sanitation, scientists also take temperature, humidity, air circulation, light, carbon dioxide, nutrients and other elements into account to create the perfect environment for growth.

A tightly controlled environment not only maximizes growth potential, but also allows scientists to create food that suits specific needs, Zheng says.

For example, scientists can lower the amount of potassium in lettuce for patients with kidney problems or increase zinc in cabbage for children by altering the nutrient solution and growing conditions.

"This is the fundamental difference between a plant factory and conventional farm," he says. "We simply have extensive control over how and when our plants can grow, and let nature run its course in the most ideal conditions."

Plants are 'picky eaters'

The requirements for plant growth fall into two broad categories: photosynthesis and soil nutrients.

The sun accounts for 90 percent of all botanic bioenergy through photosynthesis-a process in which plants combine carbon dioxide and water and turn them into carbohydrates and oxygen. Sunlight is also a bundle of different wavelengths of light, covering a wide spectrum from ultraviolet rays to infrared.

However, plants are "picky eaters that favor blue and red lights", Li says. "If we can figure out what ratio and combination of lights are best suited for each plant's growth, then we can change or create LED lights that shine at that specific intensity and spectrum, saving lots of energy in the process," he adds.

While blue and red lights are the "meat and potatoes" of a plant's growth, scientists are noticing other spectrums of light also play a subtle yet crucial role in maximizing growth and quality.

For example, scientists discovered that adding some green light to the red-blue recipe can help some vegetables grow, while too much green light puts plants into hibernation, although this is helpful for a plant's nutrient buildup.

"Mimicking sunlight using LED is very energy intensive," Li says. "At the end of the day, whoever has the most energy-efficient and productive light recipe wins."

While plant growth mostly relies on light, water and carbon dioxide, it still needs some trace elements from soilor fertilizers to be healthy. In the case of plant factories, hydroponic nutrient solutions infused with 17 essential elements, ranging from nitrogen to calcium, have replaced soil.

"The content of the nutrient solution is also tailored to suit the plant's specific needs," says Pei Kequan, a research director at the factory. Unlike the trace elements from fertilizers, which are locked in big compound molecules, "the nutrients in the solution are broken into small molecules, meaning the plant can absorb them easier and grow faster while keeping its nutrient value and taste".

In the lab, it takes around 20 days for a sapling to reach maturity, but it takes 40 to 60 days on a conventional farm. This means scientists can collect more than a dozen harvests of produce each year, compared with one to two from conventional farms, depending on the weather conditions, he says.

Moreover, scientists at the facility have built the infrastructure to monitor elements in the solution. Once an element is depleted, they can add the missing nutrient and reuse the solution without needing to make a new batch, thus reducing the cost.

zhangzhihao@chinadaily.com.cn

(China Daily European Weekly 05/12/2017 page19)

Today's Top News

- Full text: Chinese President Xi Jinping's 2026 New Year message

- Poll findings indicate Taiwan people's 'strong dissatisfaction' with DPP authorities

- Xi emphasizes strong start for 15th Five-Year Plan period

- PLA drills a stern warning to 'Taiwan independence' separatist forces, external interference: spokesperson

- Xi, Putin exchange New Year greetings

- ROK leader's visit to help boost bilateral ties