Targeting high-quality industrial development

Editor's note: The State Council Information Office invited five worker representatives from key centrally administered State-owned enterprises to share their stories as they pursued high-quality industrial development, on Thursday.

He Xiaohu, lathe operator at Xi'an Aerospace Engine Co Ltd

He Xiaohu, lathe operator at Xi'an Aerospace Engine Co Ltd

My team and I have tackled 75 technical challenges in the research, development and manufacturing of rocket engines, and applied for 25 different technological patents.

Advanced manufacturing solutions, including intelligent machining cells and automated production lines, are now extensively deployed across modern workshops.

This technological integration has elevated manufacturing quality and production efficiency while substantially reducing the intensity of manual labor.

Concurrently, this evolution requires industry workers to have precision manufacturing expertise, comprehensive knowledge systems with knowledge-sharing aptitude, as well as a capacity for tackling technical bottlenecks while driving technological innovation.

Liu Li, leader of an oil production team at Daqing Oilfield

Liu Li, leader of an oil production team at Daqing Oilfield

For over six decades, Daqing oil workers have cumulatively produced more than 2.5 billion metric tons of crude oil, accounting for one-third of the country's total crude output during the same period.

Innovation permeates every facet of our work. We have developed 1,048 technological innovations while providing advanced training to over 16,000 skilled personnel through our workshop.

Our innovation fundamentally addresses production challenges to generate tangible enterprise value. Moving forward, we will harness the digital wave and advance intelligent transformation, propelling high-quality development through digital intelligence technologies.

Li Min, team leader at the transmission and maintenance center of the ultrahigh voltage company of State Grid Shandong Electric Power Co

Li Min, team leader at the transmission and maintenance center of the ultrahigh voltage company of State Grid Shandong Electric Power Co

I encountered substantial challenges since forming a team to explore drone patrol technology in 2013.

Now, our drone patrol capabilities have advanced significantly, progressively replacing manual inspections, delivering substantial efficiency gains and enhancing security.

Moving forward, we are set to explore further application scenarios for drone technology, aiming to make the inspection and maintenance work more convenient and intelligent.

Liu Boming, deputy director of the hydraulic press forging plant of China First Heavy Industries

Liu Boming, deputy director of the hydraulic press forging plant of China First Heavy Industries

Over the past 35 years, I have pioneered 53 groundbreaking forging techniques while leading teams to overcome dozens of critical bottleneck technologies.

Certain forging operations require a very high level of technology with limited operating space. To overcome these challenges, my team and I conducted iterative experimentation, performing digital simulations and shaping critical procedures on clay modeling tools.

Having ultimately mastered cutting-edge forging techniques, and shattering a global monopoly, I am convinced that securing core proprietary technologies remains an imperative.

Yao Zhihui, vehicle electrician from CRRC Changchun Railway Vehicles Co Ltd

Yao Zhihui, vehicle electrician from CRRC Changchun Railway Vehicles Co Ltd

Assembly constitutes a core process in high-speed train production, which requires us to have a high level of skills.

The development of the CR450 electric multiple unit has relied on collective problem-solving and collaborative innovation across all divisions of our company, showing China's global leadership in high-speed rail technology.

Our efforts have ensured optimal performance across all high-speed rail functionalities while elevating the public commuting experience, which makes me proud and instills renewed confidence as we advance toward new goals.

Today's Top News

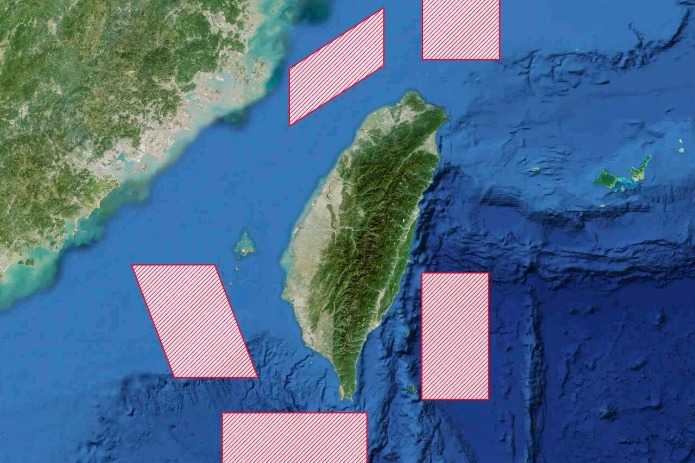

- Drills demonstrate China's resolve to defend sovereignty against external interference

- Trump says 'a lot closer' to Ukraine peace deal following talks with Zelensky

- China pilots L3 vehicles on roads

- PLA conducts 'Justice Mission 2025' drills around Taiwan

- Partnership becomes pressure for Europe

- China bids to cement Cambodian-Thai truce